| Home > My Range Rover > My L322 4.2 SC |

|

|

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

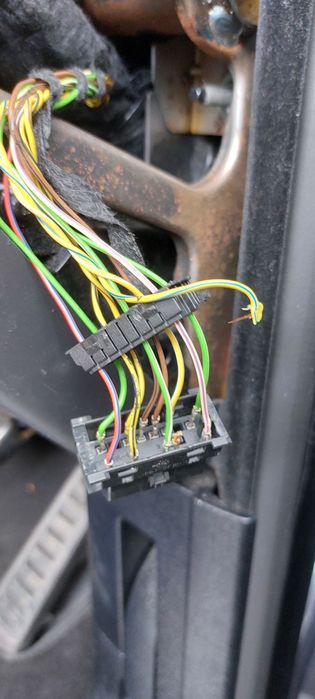

I have now removed the rear arch liner and the cill cover on the nearside.

|

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

Looking up at the cill they were like this

|

||

|

| dhallworth Member Since: 10 Oct 2011 Location: Glasgow Posts: 3349

|

Nice work!

|

||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8826

|

Caught just in time from the expensive to repair inner sills... |

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

Yes pleased about that,

|

||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8826

|

When you have it all cut out and ready to weld use weld through primer on all of it, then afterwards use the cavity protection of your choice, personally I like Dinitrol... outside, again, use whatever you like, just remember to keen an eye on it..... |

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

Yes I have some weld through primer, just wondered how much gets burnt off and how to deal with that.

|

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

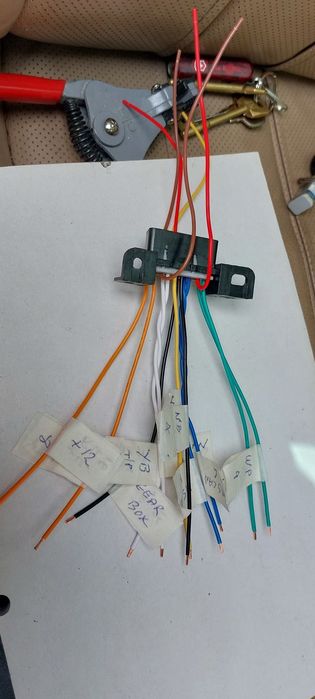

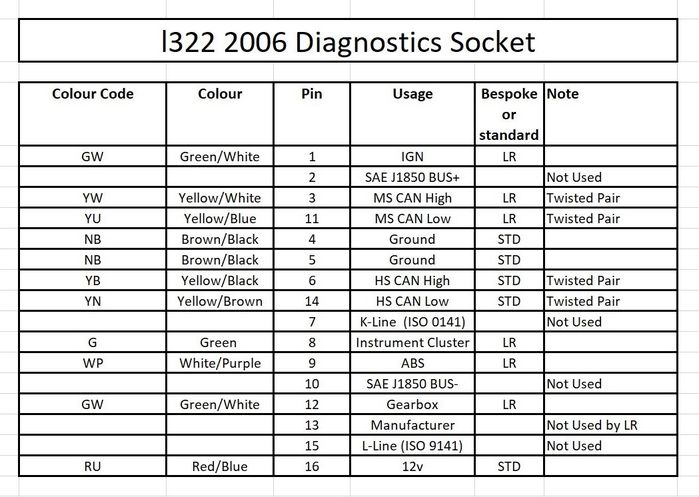

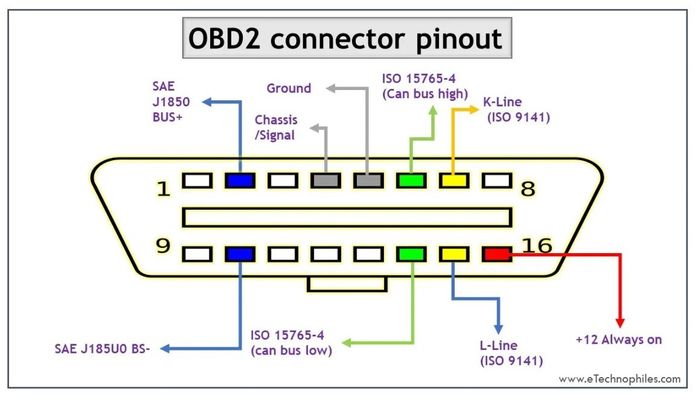

I needed to change my TV module to a newer hybrid one, so as I have to remove everything, I decided to add in the LR Water Shedder. As most of the posts covering this that I have been able to find have no pictures, or the pictures are missing I thought I would document the process.

|

||||||||||

|

| dhallworth Member Since: 10 Oct 2011 Location: Glasgow Posts: 3349

|

Nice work.

|

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

Hi David

|

||

|

| dhallworth Member Since: 10 Oct 2011 Location: Glasgow Posts: 3349

|

That’s a good idea, I hadn’t thought of that!

|

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

No problem, pleased to help. |

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

I have tried to add detailed information about my rust repairs here but for some reason I cannot upload pictures on this thread, So I created a new posting https://www.fullfatrr.com/forum/post650136.html#650136

|

||

|

| bigbo Member Since: 07 Jul 2014 Location: Derbyshire Posts: 616

|

First update in quite a while, I've been working on my wife's MG, major service and cam belt change which led to head gasket replacement.

|

||||||||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()