| 2010 Paddle Shifters Installed - Gearbox Fault when in Drive | |

Hello all,

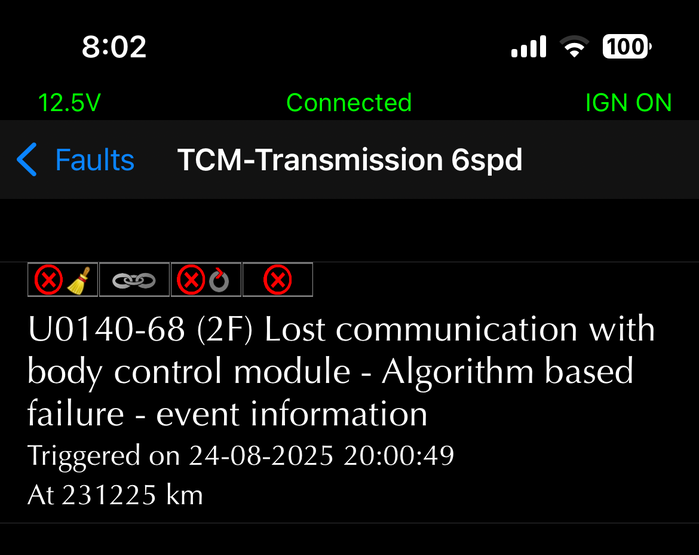

Installed paddle shifters to a 2010 L322 (5.0L V8, ZF 6 speed). Hooked up everything correctly (illumination works). Set paddle shifters to "Fitted" in the CCFs. Started the car after the CCF update procedure, get a gearbox fault (see attached) after putting it in drive. Paddles will not change gear unless the car is in sport mode at which it will only downshift, not up shift. To see if it made a difference, I changed the CCFs to "Not fitted" and the gearbox fault is gone.

Spoke with GAP Diagnostics to see if maybe the gearbox firmware needed updating, they looked it over and said I have all the correct firmware already.

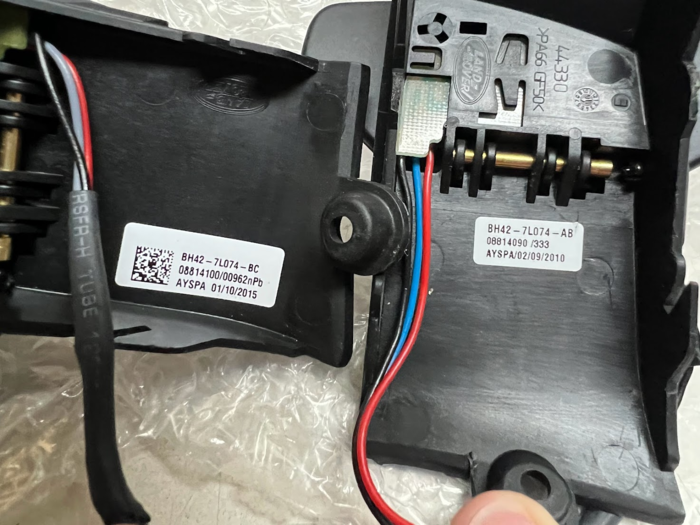

To rule out the paddles shorting something, I tried without the paddles connected at all, same issue. Did this because the paddle shifters do not communicate with the car as there are no smarts or ICs in them. They simply ground one pin for down shift, and the other pin for up shift. There are only 3 pins per paddle (illumination, ground, and the switch pin). The ground and illumination light up the LED, then the switch pin gets grounded to determine if it's been engaged. The paddles can be disconnected entirely and it should not trigger a code. As far as the car would be concerned, you just didn't pull any paddles.

Maybe the steering wheel controls (right side, where the paddle shifter wiring plugs in) are wonky?

|

![]()